Residential Subsidence

Terraced Property in Nottingham experiencing subsidence remediated by Geobear

Background

Background

A loss adjuster contacted Geobear to address a subsidence issue at a property in Nottingham. The property had suffered from structural movement at the rear of the building, due primarily to soil erosion caused by defective drainage. The subsidence was evidenced by cracks in the walls to the rear of the property, meaning an underpinning solution would be required.

A site investigation confirmed that the rear drains were washing away fines in the soil, destabilising the ground beneath the foundations.

The loss adjuster contacted Geobear to design a subsidence treatment that utilises a specialist geopolymer mitigating the need for traditional underpinning.

Geobear’s Solution

Drain monitoring

The Geobear subsidence solution is designed based on site investigation data and is minimally disruptive compared to traditional methods. Residents of the property could stay in the home whilst the subsidence repair was delivered.

Geobear designed and delivered a bespoke geopolymer injection solution to improve the ground where the washout had occurred. The designed solution involves injections of geopolymer at predetermined depths, beneath the strip foundations, of the rear of the building. Prior to the works the drainage repairs had been completed to ensure the geopolymer treatment would be effective.

In total, Geobear treated five linear metres of the perimeter wall. The injection process was monitored with laser levels to ensure there was no lifting of the building. In some instances, Geobear can complete a controlled lift of the building by calculating the expansive forces of geopolymer.

At this site, the Geobear subsidence solution was delivered within one day, and the residents of the property were both delighted and fascinated by the outcome.

Comparison to Traditional Underpinning

The Geobear solution has a multitude of benefits when compared to an underpinning solution. The duration of the work was 1 day as opposed to 3 weeks, and the comparative cost would be up to 50% less.

| Factor | Traditional Underpinning | Geobear Solution | Benefit |

| Duration | 2–3 weeks | 1 day | Faster completion |

| Disruption | High: excavation, dust, noise, skips | Minimal: no excavation, quiet process | Less disruption |

| Carbon Footprint | 1.34 tCO₂e | 0.66 tCO₂e | >50% reduction |

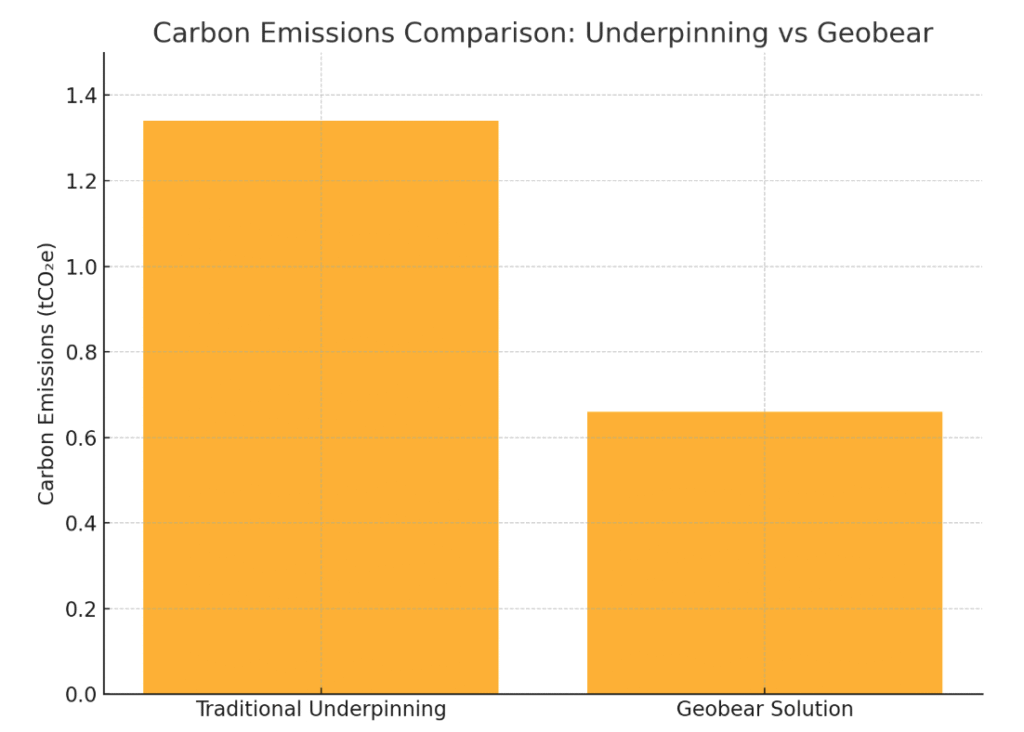

Carbon Emissions Comparison

Expanding on the carbon benefit, for this property in Nottingham, traditional underpinning to a depth of 1 metre over 5 linear metres would have generated an estimated 1.34 tonnes of CO₂ equivalent (tCO₂e). This includes emissions from:

• Concrete: ~3 m³ of material emitting 0.75 tCO₂e

• Steel reinforcement: ~300 kg of rebar, adding 0.51 tCO₂e

• Diesel for excavation: ~28 litres contributing 0.07 tCO₂e

By contrast, Geobear’s geopolymer injection method used only a fraction of the material and emitted just 0.66 tCO₂e, based on a verified emission factor of 3.07 kg CO₂e per kg of geopolymer used. This approach halved the carbon footprint while also avoiding excavation, spoil removal, and concrete curing delays.

Customer Benefits

The primary customer benefits of using Geobear for this project were:

- Zero excavation or structural risk to the building

• Work completed in a single shift

• Property could remain occupied

• Substantial savings on both cost and carbon

The Geobear solution provided a fast, cost-effective and environmentally sustainable alternative to underpinning. By resolving the ground instability through geopolymer injection, the property was stabilised with minimal disruption to the homeowner, setting a benchmark for modern subsidence remediation.

Background

Background