Campbeltown Museum & Registrar’s Office – Ground Improvement and Subsidence Mitigation

Background

The Burnet building, part of Campbeltown Museum, is a Grade A-listed building located adjacent to the dock area in Campbeltown, Scotland, and had experienced long-term subsidence issues attributed to soft ground conditions and tidal activity. Originally constructed in 1899, the structure serves multiple public functions, including a museum, council office, and venue for marriage ceremonies. The historic building had visible signs of cracking and structural stress that had developed gradually over decades, reportedly since the early 2000s.

A site investigation commissioned by Argyll and Bute Council and led by Ironside Farrar identified the ground beneath the building as being periodically compromised by high tidal events from Campbeltown Loch, which contributed to fines washout and soil weakening beneath the foundations.

Alternative Methods

Traditional solutions such as concrete underpinning, had been explored in earlier years. Concrete underpinning would have required significant excavation work, the closure of the public building for an extended period, and disruption to day-to-day operations, including staff working in council offices and ongoing ceremonies. As such, a minimal disruption approach was a fundamental requirement for the client.

Why Geobear

Minimal disruption with tubes to inject geopolymer

The benefits of a Geobear solution far outweigh traditional methods. An engineered solution is designed that utilises Geobear’s non-invasive geopolymer injection method. This approach sees material injected beneath the foundations of the building through holes drilled into the ground at pre-designed spacings. The operations of the registry office could continue unaffected whilst Geobear provided the ground improvement works, ensuring no inconvenience to the public and commercial implications for Argyle & Bute Council.

Furthermore, the Geobear solution is more sustainable, delivering a carbon footprint reduction of over 50% compared to traditional underpinning methods.

Geobear was selected not only for its technical solution but also because of its demonstrable experience with heritage buildings and sensitive environments. The client noted the quality of Geobear’s previous case studies as a deciding factor, providing confidence in the company’s capability to deliver a precise, minimally invasive solution in a challenging and high-profile environment.

Geobear Solution

Geobear acted as Principal Contractor, providing a full turnkey service that included site management, service locating, drainage enabling works, pedestrian and highways interface management, and full CDM compliance.

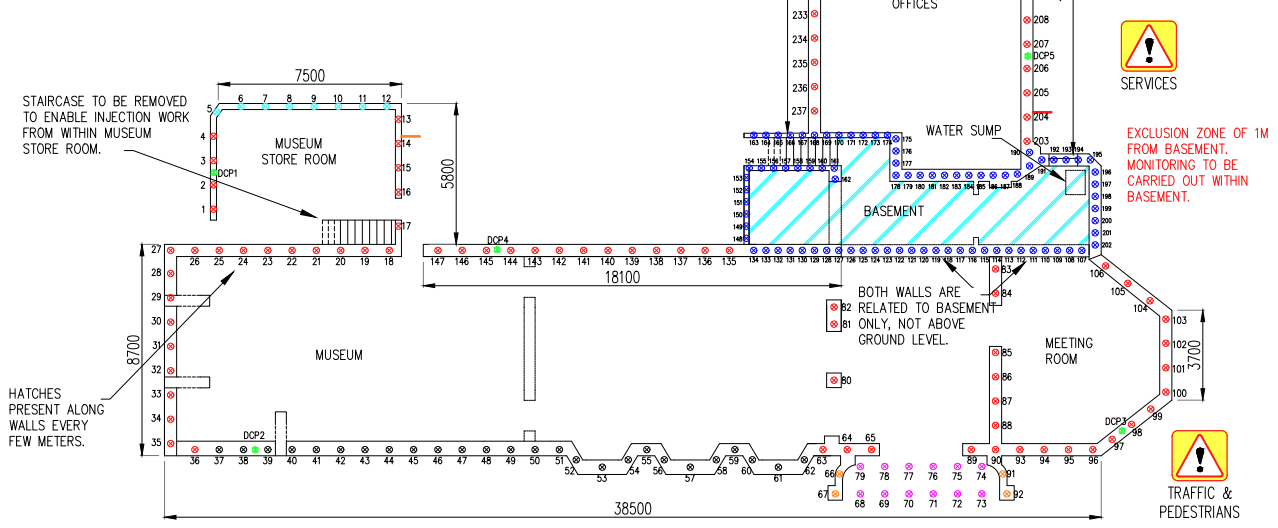

Section of treatment plan

The solution involved targeted geopolymer injection to improve soil bearing capacity beneath all primary load-bearing walls throughout the building. Over 250 injection points were installed, reaching depths of up to 2 metres below foundation level. The solution design was informed by detailed load assessments of different parts of the building, allowing for tailored injection depths, spacings, and resin volumes based on variable loading and foundation conditions.

A programme of 15 working days was agreed, with verification included pre- and post-Dynamic Probe Testing (DPT) to demonstrate improvements in ground strength. Crack monitoring and level surveying was also undertaken to monitor structural behaviour during the work and post-intervention.

Comparison with Underpinning

| Feature | Traditional Underpinning | Geobear Solution |

| Disruption | Extensive excavation | Minimal – externally injected resin |

| Duration | 6–8 weeks or more | 15 working days |

| Public Access Impact | Requires building closure | Building remained operational |

| Structural Risk | High during excavation | Low – no structural breakouts |

| Environmental Impact | High carbon emissions | Significantly lower emissions |

| Verification Methods | Visual and manual inspection | DP testing, crack/coordinate monitoring |

Carbon Savings

Based on the verified carbon assessment conducted by Carbon Footprint Ltd (2022), a traditional underpinning scheme of this scale would have produced approximately 44 tonnes of CO₂e. Geobear’s geopolymer injection method generated only 20.7 tonnes, resulting in a 53% reduction in emissions and avoiding over 23 tonnes of CO₂.

These savings were achieved by eliminating excavation, reducing concrete and steel use, and limiting time on site — supporting both environmental goals and practical delivery.

Project Video